We must first understand the components of the CALM system in order to begin the hazard identification, (HAZID) study, or risk assessment (RA) for maritime operations.

Catenary Anchor Leg Mooring (CALM) is one type of the Single Mooring System (SMS) which is a part of the Floating Production Storage and Offloading (FPSO) system.

CALM is a type of mooring system commonly employed for the transfer of crude oil, and liquefied natural gas (LNG) between tanker ships and offshore platforms or buoys.

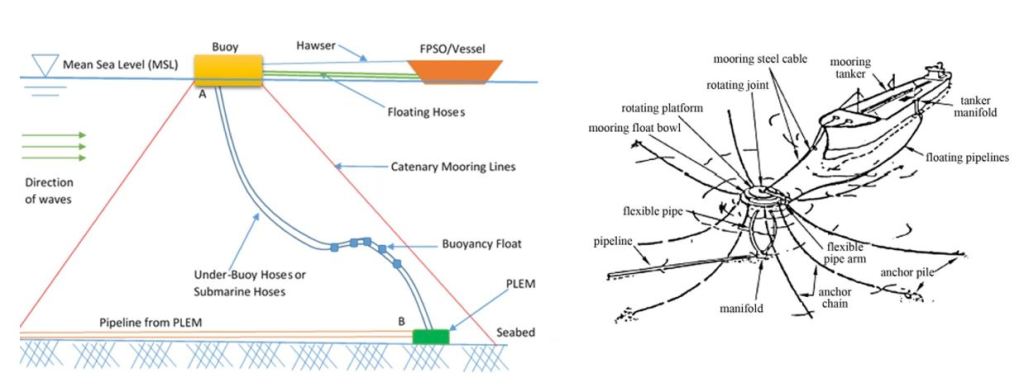

The CALM system typically consists of a floating buoy connected to the seabed by several anchor chains or cables, creating a catenary shape. Tanker ships can then moor to the buoy via a mooring line.

The CALM setup allows for the safe and efficient transfer between the tanker and the offshore facility. The CALM system can accommodate a wide range of tanker sizes and types, including single-point moorings (SPMs) and FPSO, even in rough sea conditions, including strong wind, waves, and currents as the buoy’s flexible connection to the seabed helps to adsorb the forces exerted by waves and currents.

The main components of the system are as follows;

- Buoy: The primary function of the buoy is to provide buoyant force, keeping the entire CALM afloat. The buoy serves as the connection point for mooring lines or chains that anchor it to the seabed. Buoys often include navigational aids such as lights, reflectors, or radar reflectors to enhance visibility and help marine vessels locate the CALM system, especially during low visibility or at night.

- Rotating platform: The rotating platform installed on the upper portion of the float bearing when the wind direction changes it can rotate around the center of the floor 360 degrees through the mooring force ;

- Rotary joint: The rotary joint is typically located at the transfer between the buoy and the mooring hawser or fluid transfer hose. It serves as the connection point. The rotary joint allows the rotation movement to occur without disrupting the fluid transfer process since the waves and currents can cause the rotational motion at the connection point. The rotary joint incorporates a sealing mechanism to prevent fluid leakage between the stationary and rotating components.

- Anchor chain. Anchor chains are typically attached to the buoy at one end and connected to the anchor piles or anchors on the seabed at the other end. This connection creates a secure link between the buoy and the seabed. The anchor chains are arranged in a catenary configuration, commonly six chains composed of many links.

- Anchor pile: Anchor piles serve as anchor points for the mooring lines or chains that extend from the floating buoy to the seabed. These mooring lines are typically arranged in a catenary configuration, providing a flexible connection that allows the buoy to move with the waves and currents while maintaining its position relative to the seabed.

- Hose: CALM hoses are designed to handle high-pressure offshore oil and gas material transferring. They are engineered to withstand the hydraulic forces generated during fluid transfer and maintain their structural integrity, even though they are bent and flexed with the movement of the waves and currents. CALM hoses are typically made of durable and corrosion-resistant material. These materials are chosen for their ability to withstand exposure to seawater, UV radiation, and harsh environmental conditions.

- Buoyancy tank: The buoyancy tank provides the necessary buoyant force to keep the CALM buoy afloat by displacing water equal to its weight, the buoyancy tank ensures that the buoy remains stable and upright, even in rough sea conditions.

General environmental hazards to CALM

The following are the general environmental hazards of CALM operations that are identified during hazard identification (HAZID) or risk assessments (RAs).

Storms and Extreme Weather: Severe weather conditions such as hurricanes, typhoons, and strong storms can subject CALM systems to high wind, large waves, and intense currents. These environmental forces can exert significant loads on the mooring lines, buoys, and anchoring system, potentially leading to damage or failure.

Corrosion: The marine environment exposes CALM components, such as chains, cables, and buoys, to corrosion. Corrosive agents in seawater, such as salt, can degrade and structural integrity of these materials over time, increasing the risk of failure if not properly monitored and maintained.

Wave and Current Loading: CALM systems are designed to accommodate wave-induced motions and dynamic loads. However, extreme wave conditions or strong currents can exceed design parameters, leading to excessive stress on the mooring lines, buoys, and anchoring system.

Vessel Collisions: CALM buoys and associated infrastructure are vulnerable to collisions with vessels, including tankers, supply vessels, or other marine traffic. A collision can cause structural damage to buoys or its mooring system.

Subsea Hazards: Subsea hazards such as underwater obstructions, pipelines, and geological features can pose risks to CALM systems during installation, operation, and maintenance activities.

Siltation and Seabed Instability: Changes in seabed conditions, such as siltation, sedimentation, or subsidence, can affect the stability of the CALM anchoring system. Seabed instability may lead to anchor drag, loss of holding capacity, or misalignment of mooring lines, potentially compromising the safety and reliability of the mooring system.