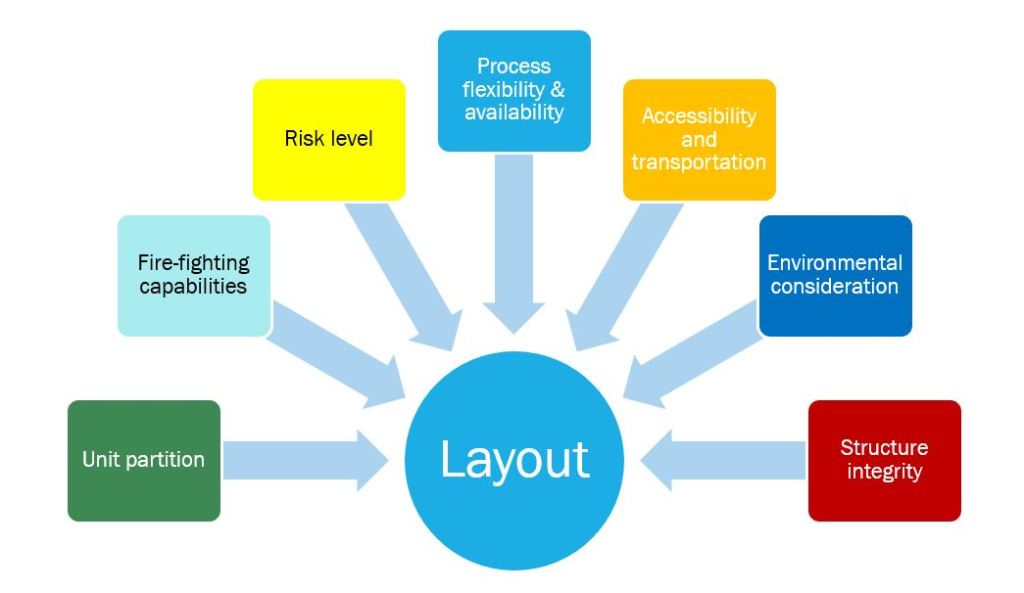

The design of offshore facility layout involves several key elements to ensure unit partition, fire-fighting capabilities, risk level, process flexibility & availability, accessibility& transportation, environmental consideration, and structure integrity. However, at the very end point of the safety, the installation should minimize the potential of gas release or smoke drifting toward the accommodation and primary evacuation point.

If the ingress of smoke or gas is possible, the design of any ventilation system shall take into account since the amount of ventilation available and degree of congestion are significantly influence the severity of an explosion.

To reduce the potential of hazards, the goal is to achieve segregation of fuel ignition sources by separating groups of equipment and defining the compatibility of units between each other. Examples of the separation are the following which are defined from (Fuel Source VS Ignition Source).

- Wellhead (FS)

- Unfired process (FS): Manifold, header, separator, exchanger, pump, compressor, slug catcher, metering, etc.

- Hydrocarbon Storage (FS): Produced water tank, sump tanks, etc.

- Fired process (IS): Fired heater.

- Machinery and power generation (IS): Generator, Air Compressor, Engine, etc.

- Working area and utility equipment unit (IS)

- Pipeline and riser (FS): Riser, Pig launcher, pig traps

- Vent and Flare (FS & IS)

- Transportation (IS)

If the units that are located beside each other are compatible (FS + FS) or (IS + IS), they can be located in the same fire zone. If the case is (FS + IS), a detailed study shall be performed such as locating those two different fire zones, considering the safety distance, performing the quantitative risk assessment, etc.

Working Area

- Central Control Room (CCR): This room is a central hub or nerve center located on the offshore platform, where operators monitor and control various aspects of the facility’s operation.

- Switchgear room: This room contains all electrical switchboards to distribute generated power to users.

- Battery room: This room contains battery racks for the Uninterrupted Power Supply (UPS) system. It shall be ventilated to avoid hydrogen concentration.

- UPS room: Dedicated switchboard for system fed by UPS are located in this room.

- Telecommunication room: This may contain the telecom console, and the video/radio transmission facilities.

- Workshop: This room shall be separated for maintenance and repair activities. It should be separated by function such as Mechanical workshop, HVAC workshop, Instrument Workshop, Electrical Workshop, and etc.

Utility Equipments Area

- Firewater pump: Based on NFPA, each living quarter (LQ) shall have a dedicated firewater pump with a redundant system and shall be placed at a suitable distance from the (PP) production platform.

- Potable water maker: It shall be installed in a small shelter and placed at the highest elevation for the benefit of gravity pressure.

- Gray/black water disposal system: Gray (kitchen, shower, etc.) and black water (toilet) shall be designed with gravity flow and end at the sewage treatment system

- Equipment lift: This is installed in case the pedestal crane and laydown areas cannot transfer to LQ.

- Aviation refueling station/tank: It is only installed at the highest elevation for quick assess to a helicopter which shall be at a remote location.

Vent and Flare area

- Flare platform shall be located far away from production platform (PP);

- Ensure that the wind is blowing flare gases away from the complex;

- Flare should not be located down-wind of sources of flammable gas;

- Cold vent are also considered as the source of release and could become ignition source in case of accidental igition.

Transportation Area

- Boat landing: Also known as a marine transfer station where boats or vessels can safely dock, load, and unload passengers, cargo, equipment, or supplies. Key features of boat loading include.

- Docking area: The docking area is typically equipped with fenders or bumpers to prevent damage to both the boat and the offshore structure docking maneuvers.

- Mooring and Berthing Equipment: Boat landing may include mooring bollards, cleats, or padeye to secure boats in place once they are docked. Mooring lines or ropes are used to tie the boat securely to the offshore structure. This activity shall be very careful since during extreme weather conditions the workboat may drift uncontrolled and clash with the platform (PF)

- Access Equipment: Boat landing often have gangways, stairs, or ramps to facilitate the safe boarding and disembarkation of passengers between the boat and the offshore platform.

- Lighting and Signage: Boat landing may equipped with lighting system to ensure visibility and safety during nighttime or low-light conditions.

- Location: The location of boat landing area should be installed at the opposite side of the flare, and consider the risk of vent, exhaust location, wind, sea swell, current direction, and hazardous area, including wire-line operations.

- Ship impact and dropped objects: The risers and conductor should be designed and positioned or minimize the likelihood of damage due to ship impact and drop objects.

- Air Transfer: Air transfer refers to the transportation of personnel or cargo via helicopters between onshore bases and offshore facilities.

- Helipads and landing facilities: Helipads or designated landing area to accommodate helicopter landings and takeoffs shall be equipped with lighting, marking, and safe

- Location: The location of the helicopter approach shall consider the risk of flare, vent, exhaust location, wind direction, and hazardous area. The 210o approach shall be free, up to 1 km away, of any obstacle.

- Safety Feature: The safety feature that should be installed on the helipad such as;

- Safety Net and Barriers: To prevent from personnel and equipment falling off the platform which should be installed in a cantilevered position.

- Fire Suppression System: such as foam monitors or fire extinguishers.

- Tie-Down point: Tie-down point or anchoring system shall be provided to secure the helicopter in place during adverse weather condition.

- Weather Monitoring Equipment: such as windsocks, anemometers, and visibility sensors should be installed near the helipad to provide real time weather data to pilots.

- Emergency Lighting and Signage