What is the Gas Lift Operation?

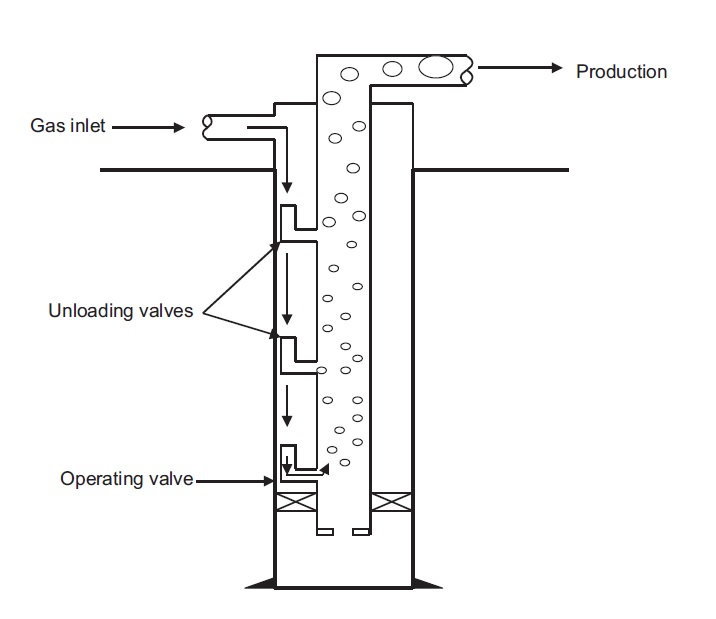

Gas Lift operation is a widely used artificial lift method in the oil and gas industry to increase or maintain the production rate of oil wells.

It involves injecting gas into the wellbore to reduce the hydrostatic pressure of the fluid column (the specific gravity is lowered), thereby allowing the reservoir fluids (oil and associated gas) to flow more easily to the surface. This is because of the injected gas encounters the produced fluid (oil and water) in the wellbore. At a certain depth, known as the bubble point depth, the pressure of the injected gas equals the pressure of reservoir fluid, causing the gas to come out of the solution and form bubbles.

Gas Lift system components

The basic equipment for gas lift operation includes the following;

- Gas Lift valve (GSV), a pressure regulator device installed on a gas lift mandrel on the tubing string of a gas lift well. There are 4 types of GSV which are 1) casing pressure-operated valve 2) throttling flow valve 3) fluid-operated valve, and 4) combination of fluid-open/pressure-closed valve.;

- Wire-line adaptations, a tool to retrieve a dummy valves after finishing the hydrotesting process and use to install the gas lift valves.

- Check valves on the gas lift vale, to protects against black flow from the tubing to the annulus;

- Gas Lift mandrels, a container in the tubing string that holds a gas lift valve. The conventional type of Gas Lift mandrel is the side-door type, the mandrel system comprised of Gas Lift Valve (GSV), check valve, mandrels itself.

- Surface control equipment; and

- Compressor

The most common failure and cause loss of lifting efficiency

Gas lift system can experience various types of failure or issues that may affect their performance and reliability. Some of most common failure or problem associated with the gas lift operation include:

- Gas Compression Issues: Insufficient gas supply or inadequate compression can lead to reduce the gas lift effectiveness since it will reduce gas injection rates and suboptimal lift performance. The example causes are following.

- Gas lift wrong design (larger than actually needed);

- Hydrate;

- Unstable of gas lift supply pressure;

- Problem at surface injection flow control valve;

- Wrong set point (high/low gas injection flow rate);

- High pressure in well head

- Problem at gas lift valve (e.g. salt deposition, stuck open due to dirt accumulation)

- Gas Leak: Leaks in the gas lift tubing, connections, or surface equipment can lead to loss of gas pressure and reduced injection rates. The example causes are following.

- Gas lift valve stuck in open position due to salt deposition or dirt accumulation;

- Gas lift valve faulty

- Liquid loading: Liquid loading occurs when liquid (e.g. water, condensate) accumulate in the wellbore, obstructing gas flow and reducing life efficiency. Liquid loading can occur due to factors such as declining reservoir pressure, high-gas-to-liquid ratios, or insufficient gas velocity to carry liquids to surface.

- Gas Interference: Gas interference occurs when gas bubbles coalesce and form large gas slugs in the tubing, causing flow instability and decreased lift efficiency.

- Downhole Tubing Damage: Corrosion, erosion, or mechanical damage to downhole tubing can compromise the integrity of the gas lift system and reduce it effectiveness.