In functional safety engineering, the failure rate is a key parameter in determining the probability of a system failing to perform its safety functions when needed.

In the context of reliability engineering, it is also aimed to understand and manage the reliability of a system and components, ensuring that they perform their intended functions without failure over a specific time period. Hence, the failure rate is a crucial metric in assessing and predicting the reliability of a system.

Hence, in the context of both functional safety engineering and reliability engineering, the failure rate refers to the frequency at which a system, component, or device fails during specific period of operation. It is often expressed as the number of failures per unit of time, such as failures per hour or failures per million hours of operation (FIT).

Example-1

Determine the failure of a new installation proximity switch in the green field project over the first operation month. Below is the record data.

Failure Rate Characteristics

The “bath curve” is a concept often used in reliability engineering to describe the failure rate characteristics of a product or system over its lifecycle where the bath curve consists of three distinct phases:

- Infant Mortality Phase (Early Life Failure): In the initial phase, there is a higher likelihood of failures. Failures during these periods are often due to manufacturing defects, design flaws, improper installation, and commissioning.

- Normal Life Phase: Following the infant mortality phase, there is a period where the failure rate remains relatively constant. This is often referred to as the “Normal life”.

- Wear-Out Phase: As the product approaches the end of its expected life, there is an increase in the failure rate. This is because components may degrade, or wear out.

Relation of Failure Rate and Reliability

Type of Failure

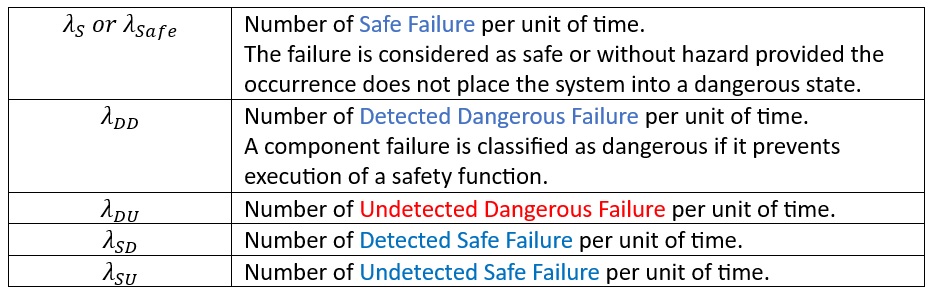

Failures are separated into two significant categories which are Safe and Dangerous.

Safe Failure refers to the failures that lead the system into a safe state, preventing or mitigating the risk of a hazardous event.

Dangerous Failure refers to the failures that could potentially lead to a hazardous condition if the system does not respond appropriately.

Example-3

Below is the example failure mode of a transmitter with provision low-trip function.

| Instrument Failure Mode | SIF Failure Mode |

| Frozen output | Fail-Danger |

| Output to upper limit | Fail-Danger |

| Output to lower limit | Fail-Safe |

| Diagnostic failure | Annunciation |

Safe Failure Fraction (SFF)

The Safe Failure Fraction (SFF) is a measure of the fraction of a system’s failures that result in a safe state or do not lead to dangerous or hazardous conditions. The Safe Failure Fraction is expressed as the following formula.