Failure Mode and Effect Analysis or FMEA is a systematic method used in some industries such as manufacturing, automation, aerospace, etc to evaluate and prioritize the potential of failure modes in a process, product, or system and their potential impact on performance.

The primary goal of FMEA is to identify and address potential problems before they occur, with the ultimate aim of improving reliability and preventing failures.

The FMEA workflow

- Identifying Components and Functions: List all components or processes involved in the system, and identify their functions.

- Identifying Failure Mode: For each component or process, identify potential failure modes (Ways in which the component or process could fail to perform its intended function)

- Identify the Potential Cause: The team brainstorms and lists the potential cause or scenario associated with the equipment, system, or process.

- Identify the Potential Effect: The team identifies the potential effect of each identified cause. The potential effect may be within or over the equipment/system.

- Determine the recommendation: The team evaluates the gap or the further recommendation that be implemented.

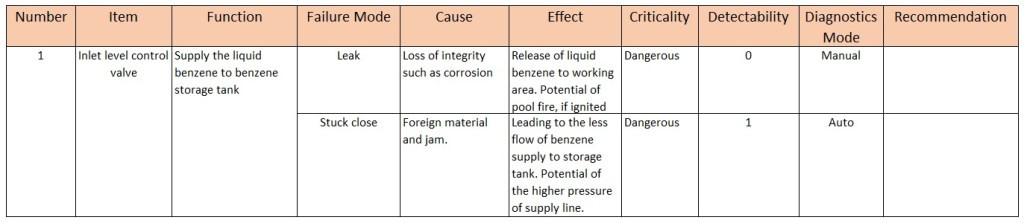

FMEA Study Worksheet

Example of equipment where FMEA is commonly used

Automotive industry:

- Engine system

- Transmission system

- Braking system

- Electronic Control Unit (ECU)

Aerospace Industry

- Aircraft engines

- Flight control system

- Hydraulic system

Railway System

- Locomotive

- Signaling system

- Brake system

Electronics and Telecommunication

- Telecommunication network

- Printed Circuit Boards (PCBs)

- Electronic Control System

- Power supply

FMEA Standards

MIL-STD 1629: Procedures for performing a failure mode and effect analysis

IEC 60812: Procedure for failure mode and effect analysis (FMEA)

SAE ARP 5580: Recommended failure modes and effects analysis (FMEA) practices for non-automobile applications

FMEA Extensions to FMECA and FMEDA

FMECA or Failure Mode, Effects, and Criticality Analysis: FMECA extends the traditional FMEA by incorporating criticality analysis. Criticality refers to the assessment of the consequences of a failure, taking into account the probability of occurrence and the ability to detect the failure before it leads to severe consequences.

FMEDA or Failure Mode, Effects, and Diagnostic Analysis: FMEDA is a specialized form of analysis commonly used in the context of safety-critical systems. It includes an evaluation of the diagnostic ability of any automatic online diagnostic or manual proof test.

Failure Mode, Effects, and Criticality Analysis (FMECA)

Additional working steps from the FMEA need to be done.

- Assessing Severity (S): Evaluate the potential consequences or impact of each failure mode on the overall system. Assign a severity rating based on the potential harm or consequences.

- Assessing Occurrence (O): Estimate the likelihood or frequency of each failure mode occurring. Assign an occurrence rating based on historical data, experience, or expert judgment.

- Assessing Detection (D): Evaluate the likelihood or potential of detecting each failure mode before it causes harm or damage. Assign a detection rating based on the effectiveness of existing detection methods or systems.

- Calculating Risk Priority Number (RPN): Multiply the severity, occurrence, and detection ratings to calculate a Risk Priority Number (RPN) for each failure mode. This helps prioritize which failure modes to address first.

- Prioritizing Actions: Focus on addressing the high-risk failure modes with the highest RPN values. Develop and implement corrective actions to reduce the likelihood of occurrence, improve detection, or mitigate the severity of consequence.

FMECA Standards

BS 5760-5: Guide to failure modes, effects, and criticality analysis (FMEA and FMECA)

Failure Mode, Effects, and Diagnostic Analysis (FMEDA)

The results of detectability are emphasized in the column Detectability and Diagnostic Mode with a number 1 to designate that this failure is detectable and a number 0 if the failure is not detectable.