To evaluate the Safety Integrity Level will meet the SIL requirement to reduce the risk to an acceptable level. 3 things are required to be verified.

- Probability of Failure on Demand average (PFDavg);

- Architecture Constraints;

- Systematic Capability (SC).

Probability of Failure on Demand average (PFDavg)

The performance or effectiveness of SIL is presented by the Probability of Failure on Demand (PFD).

| SIL Level | PFDavg (Low Demand) | RRF | PFHavg (High Demand) |

| 1 | <10-1 to < 10-2 | >10 to 100 | <10-5 to < 10-6 |

| 2 | <10-2 to < 10-3 | >100 to 1,000 | <10-6 to <10-7 |

| 3 | <10-3 to < 10-4 | >1,000 to 10,000 | <10-7 to <10-8 |

| 4 | <10-4 to <10-5 | >10,000 to 100,000 | <10-8 to <10-9 |

Architecture Constraints IEC 61508

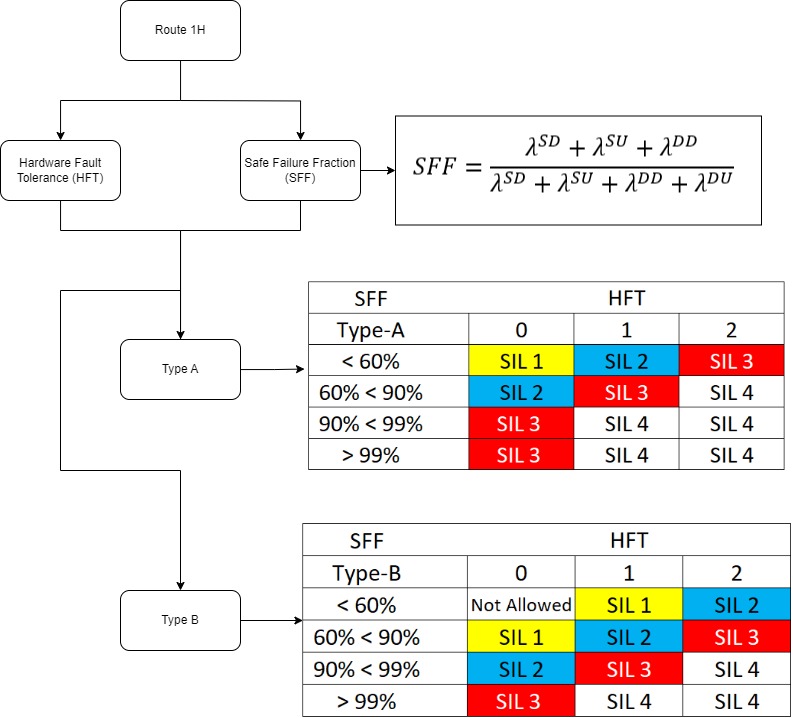

IEC 61508:10 provides two alternative approaches called Route 1H and Routh 2H.

Route 1H application to new technology devices which users did not have experience with. Hence, it will be based on Hardware Fault Tolerance (HFT) and Safe Failure Fraction (SFF) values.

The HFT indicates the number of dangerous failures the architecture can withstand before losing the ability to perform the safety function.

IEC 61508 defines two categories of devices, Type A and Type B.

- Type A: A subsystem that all possible failure modes can be determined for all constitute components i.e. solenoid, whereas;

- Type B: A subsystem that has behavior under fault conditions that can not be completely determined for at least one component i.e. logic solver

Route 2H is based on reliability data from field feedback on similar devices. It recognized the real need for the redundancy. Hence, the SFF metric is not used.

IEC 61508 Route 2H

| SIL | Mode | Minimum HFT |

| 1 | Any | 0 |

| 2 | Low-Demand | 0 |

| 2 | High or Continuous | 1 |

| 3 | Any | 1 |

| 4 | Any | 2 |

Architecture Constraints IEC 61511

It can be clearly seen that IEC 61511: 2016 was derived from IEC 61508: 2010 Route 2H.

| SIL | Mode | Minimum HFT |

| 1 | Any | 0 |

| 2 | Low-Demand | 0 |

| 2 | High or Continuous | 1 |

| 3 | Any | 1 |

| 4 | Any | 2 |

Systematic Capability (SC)

The term Systematic Capability (SC) in an IEC 61508 means that the design, test, and manufacturing processes used to create and build the product have a level of integrity needed for the required SIL. Hence, the Systematic Capability or SC can be found in product certification from the manufacturer.