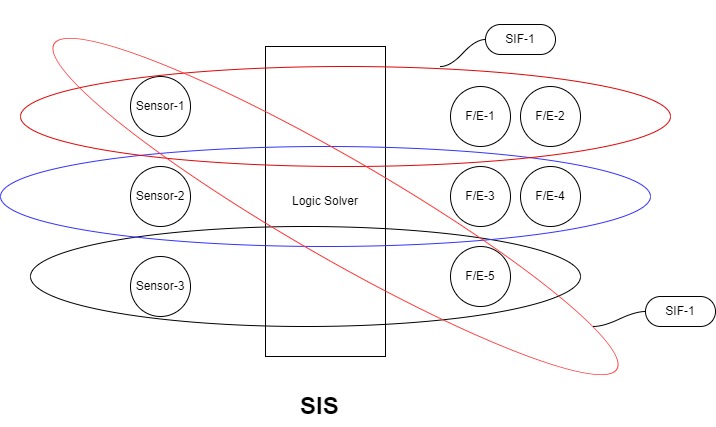

SIL (Safety Integrity Level) คือ ระดับความน่าเชื่อถือของระบบความปลอดภัย ที่ใช้บ่งชี้ว่า ระบบนั้นสามารถลดความเสี่ยงจากอุบัติเหตุร้ายแรงได้มากน้อยเพียงใด โดยเป็นค่าที่กำหนดตามมาตรฐานสากล IEC 61508 และ IEC 61511 ซึ่งระบบที่กล่าวถึงเป็นระบบทำงานด้วยเครื่องมือวัด หรือ เรียกว่า Safety Instrumented System (SIS) ที่ใช้ลดความเสี่ยงของกระบวนการผลิต โดยทำงานผ่าน “ฟังก์ชันความปลอดภัยแบบใช้เครื่องมือวัด” หรือ Safety Instrumented Function (SIF) หลายฟังก์ชัน

SIS and Risk Reduction

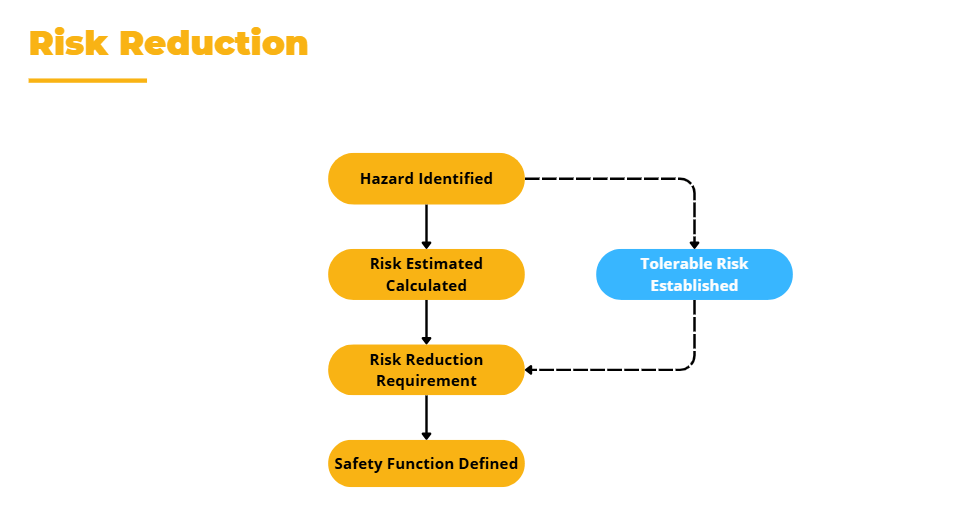

ความจำเป็นของการมี Safety Instrumented Function (SIF) ในระบบ Safety Instrumented System (SIS) ตั้งต้นจากการชี้บ่งอันตราย Hazard identified แล้วจะมีการประเมินความเสี่ยงด้วยวิธีต่างๆ เช่น Risk Ranking (Risk Matrix) หรือการประเมินเชิงปริมาณ Quantitative Risk Assessment (QRA) หรือการประเมินกึ่งเชิงปริมาณ Semi-Quantitative Risk เช่น ในระหว่างการศึกษา Layer Of Protection Analysis (LOPA)

ซึ่งในระหว่างนั้นเราต้องทำการเปรียบเทียบกับเกณฑ์ความถี่ที่ยอมรับได้ Tolerable Risk Acceptance Criteria ซึ่งถ้าพบว่าความเสี่ยงที่ได้ยังไม่อยู่ในเกณฑ์ที่ยอมรับได้ เราก็จำเป็นต้องมีระบบป้องกันเพิ่มเติม โดยตัวอย่าง ระบบป้องกันเพิ่มเติม ได้แก่

- Basic Process Control System (BPCS)

- Alarm and operator action

- Mechanical Protection i.e. PSV

- Safety Instrumented System (SIS)

จะเห็นได้ว่าจังหวะนี้ ระบบการหยุดเครื่องจักรอัตโนมัติด้วยเครื่องมือวัด หรือ Safety Instrumented System (SIS) จะเข้ามาเพื่อช่วยให้ความเสี่ยงของเราต่ำลงจนไปอยู่ในเกณฑ์ที่ยอมรับได้

Safety Integrity Level (SIL)

คำถามถัดไปคือการระบุ Performance requirement ของ Safety Instrumented Function (SIF) ที่อยู่ในระบบการหยุดเครื่องจักรอัตโนมัติด้วยเครื่องมือวัด หรือ Safety Instrumented System (SIS) ที่เรียกว่า Safety Integrity Level (SIL)

หรือกล่าวอีกนัยหนึ่งคือ การระบุ Safety Integrity Level (SIL) คือการบอกปริมาณหรือระดับความเสี่ยงที่ลดลง Risk Reduction ที่ต้องการเพื่อนำความเสี่ยงไปอยู่ในเกณฑ์ที่ยอมรับได้

โดย SIL จะมีด้วยกัน 4 ระดับ ตั้งแต่ SIL-1 จนถึง SIL-4 โดยที่ SIL-4 จะมีค่าสูงสุด (มีความสามารถสูงที่สุด) ดังนั้นแล้วถ้าความเสี่ยงยังมีความห่างกับเกณฑ์ที่ยอมรับได้สูง ก็ต้องพิจารณา SIL ที่มีระดับสูงเข้ามาใช้

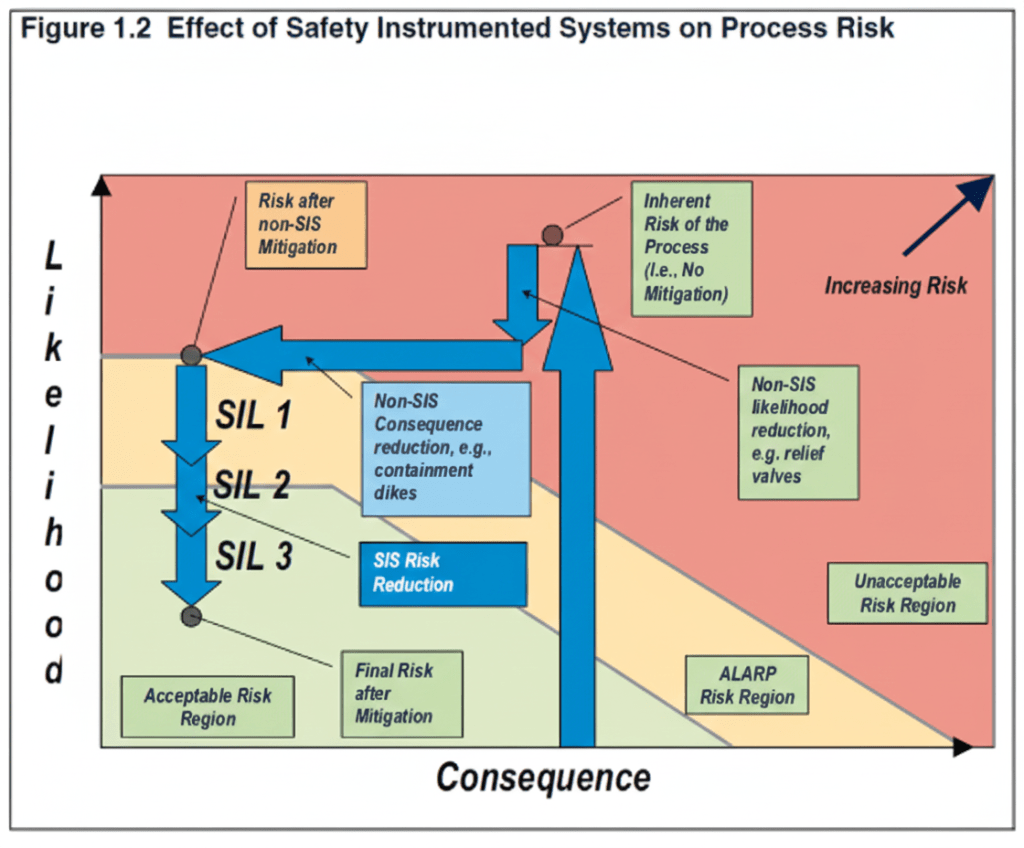

จากตัวอย่างดังรูป ความเสี่ยงเริ่มต้น Inherent Risk อยู่ในพื้นที่ที่ยอมรับความเสี่ยงไม่ได้ Unacceptable Risk การเพิ่มเติมอุปกรณ์ เช่น Pressure relief valve จะทำให้ความถี่ (Likelihood) ลงลง และการมีระบบป้องกันการรั่วไหล Containment, dike จะสามารถลดความรุนแรง (Consequence) โดยเลื่อนจุดไปอยู่ทางด้านซ้าย

แต่ถ้าความเส่ี่ยงที่ได้ยังไม่อยู่ในเกณฑ์ที่ยอมรับได้ การเพิ่มระบบการหยุดเครื่องจักรอัตโนมัติด้วยเครื่องมือวัด Safety Instrumented System (SIS) เข้ามาก็สามารถเลื่อนจุดลงมาในแนวดิ่งจนถึงเกณฑ์ที่ยอมรับได้ Acceptable Risk Region ได้

จากตัวอย่าง เพิ่ม SIL-1 นำ Risk ไปอยู่ในช่วง ALARP Risk Region เพิ่ม SIL-2 นำ Risk ไปอยู่ด้านบนของ Acceptable Risk Region แต่ถ้าเพิ่ม SIL-3 สามารถลงมาลึกได้มากกว่า

ประสิทธิภาพหรือประสิทธิผลของ Safety Instrumented Function (SIF) ที่เรียกว่า SIL แสดงโดยความน่าจะเป็นที่จะเกิดความล้มเหลวเมื่อมีความจำเป็นต้องใช้ หรือ Probability of Failure on Demand (PFD) หรือจะเรียกได้ว่า ค่า PFD เป็นตัวชี้วัดที่ใช้ในการบอกความน่าเชื่อถือของฟังก์ชันความปลอดภัย ที่จะไม่ทำงานตามวัตถุประสงค์ได้เมื่อมีความจำเป็นต้องใช้ ดังแสดงตามตารางข้างล่าง

| SIL Level | PFDavg (Low Demand) | RRF | PFHavg (High Demand) |

| 1 | <10-1 to < 10-2 | >10 to 100 | <10-5 to < 10-6 |

| 2 | <10-2 to < 10-3 | >100 to 1,000 | <10-6 to <10-7 |

| 3 | <10-3 to < 10-4 | >1,000 to 10,000 | <10-7 to <10-8 |

| 4 | <10-4 to <10-5 | >10,000 to 100,000 | <10-8 to <10-9 |

ตีความได้ว่า ยิ่งมีค่า SIL สูงเท่าไร ระดับความน่าเชื่อถือของ SIF นั้นยิ่งสูงมากเท่านั้น (โอกาสที่จะเกิดฟังก์ชั่นเสียเมื่อมีความต้องการใช้งาน PFD มีค่าต่ำมากๆ)

จากตารางจะมีคำว่า “Low Demand” หมายถึง สถานการณ์ที่ฟังก์ชันความปลอดภัยหรือระบบเครื่องมือความปลอดภัยถูกเรียกใช้งานไม่บ่อยนัก เช่นปีละครั้ง หรือหลายๆปีครั้ง หรือก็คือ ความถี่ในการเกิดเหตุการณ์หรืออุบัติเหตุไม่บ่อยมาก เช่น ในโรงงานปิโตรเคมี เป็นต้น

กลับกัน คำว่า “High Demand” หมายถึง สถานการณ์ที่ฟังก์ชันความปลอดภัยหรือระบบเครื่องมือความปลอดภัยถูกเรียกใช้งานบ่อยครั้งหรืออย่างต่อเนื่อง หรือเป็นฟังก์ชั่นด้านความปลอดภัยที่ต้องใช้งานตลอดเวลา เช่น เครื่องบิน โดยจะมีการเปลี่ยนเทอมการเรียกจาก Probability of Failure on Demand (PFD) เป็น Probability of Failure per Hour (PFH)

SIS, SIF, and SIL

สรุปได้ว่า “ระบบความปลอดภัยแบบใช้เครื่องมือวัด” หรือ Safety Instrumented System (SIS) คือระบบความปลอดภัยโดยรวมที่ครอบคลุม “ฟังก์ชันความปลอดภัยแบบใช้เครื่องมือวัด” หรือ Safety Instrumented Function (SIF) หลายฟังก์ชัน แต่ละ SIF ได้รับการออกแบบมาเพื่อจัดการกับอันตรายเฉพาะ และได้รับมอบหมาย “ระดับความสมบูรณ์ด้านความปลอดภัย” หรือ Safety Integrity Level (SIL) ตามการลดความเสี่ยงที่ต้องการ ความสัมพันธ์สามารถสรุปได้ดังนี้ SIS > SIF > SIL โดยที่ SIFs เป็นส่วนประกอบของ SIS และ SIL เป็นมาตรการที่กำหนดให้กับ SIF แต่ละรายการ

| SIS | SIF | SIL | |

| Scope | Entire system | Specific function | – |

| Component | Overach SIF | Sensor+Logic solver+Final Element | – |

| Function | Manage overall | Implement a specific function | – |

| Measurement | – | – | 1, 2, 3, or 4 |